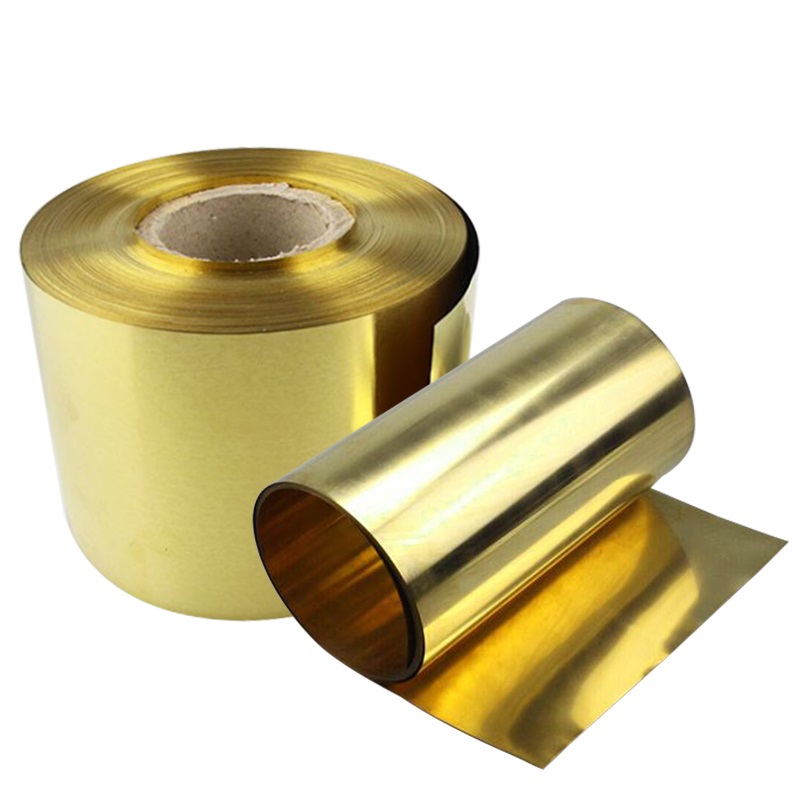

Product Description

Brass strip is used for numerous applications including construction and architecture, auto manufacturing, plumbing, builder’s hardware and electrical components. Created by alloying copper and zinc, brass strip provides high corrosion resistance, good durability, good electrical conductivity, and along with a shiny, decorative appearance. Brass strip is generally very easy to cut, machine, and fabricate.

Our brass strip and brass foil are available in thickness from 0.16mm to 3.0mm, and with temper in 1/4 hard, 1/2 hard, 3/4 hard and hard, conform to ASTM B36 standard.

Material

Copper Alloy | Chemical Composition | |||

Copper % | Lead % | Iron % | Copper % | |

C26000 | 68.5-71.5 | ≤0.07 | ≤0.05 | remainder |

C26800 | 64.0-68.5 | ≤0.15 | ≤0.05 | remainder |

C27200 | 62.0-65.0 | ≤0.07 | ≤0.07 | remainder |

C28000 | 59.0-63.0 | ≤0.30 | ≤0.07 | remainder |

Key Feature

High corrosion resistance, good durability

Shiny, decorative appearance

Strong sea-worthy wooden case for maximum protection

Thickness available from 0.16mm to 3.0mm for brass strip in roll

Full range of temper: 1/4 hard, 1/2 hard, 3/4 hard and hard

Standard: ASTM B36

Technical Properties

Copper Alloy | Temper | Tensile Strength | |

MPa | inch-pound units | ||

C26000 | 1/4 Hard | 340-405 | 49-59 |

1/2 Hard | 395-460 | 57-67 | |

3/4 Hard | 440-510 | 64-74 | |

Hard | 490-560 | 71-81 | |

C26800 | 1/4 Hard | 340-405 | 49-59 |

1/2 Hard | 380-450 | 55-65 | |

3/4 Hard | 425-495 | 62-72 | |

Hard | 470-540 | 68-78 | |

C27200 | 1/4 Hard | 340-405 | 49-59 |

1/2 Hard | 385-455 | 56-66 | |

3/4 Hard | 435-505 | 63-73 | |

Hard | 485-550 | 70-80 | |

C28000 | 1/4 Hard | 345-425 | 50-62 |

1/2 Hard | 400-485 | 58-70 | |

3/4 Hard | 415-515 | 60-75 | |

Hard | 485-585 | 70-85 | |

Specifications

Alloy | Form | Temper | Size (mm) | ||

Thickness | Width | Length | |||

C26000, C26800, C27200, C28000 | brass strip brass coil | Hard, 3/4 Hard, 1/2 Hard, 1/4 Hard | 0.16- 0.5 | ≤600 | Roll |

≥0.5 - 3.0 | ≤1000 | Roll | |||