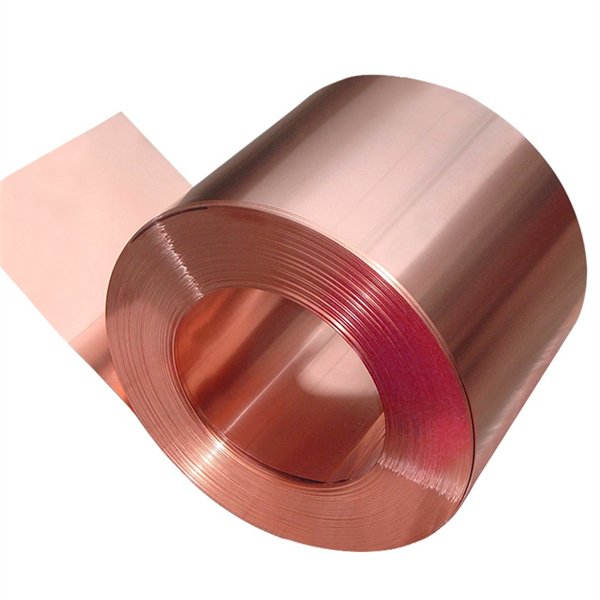

The copper strip is in form of rolls. It is used for a variety of applications including construction and architecture, auto manufacturing, electrical components, marine applications and HVAC systems. The high purity (99.92-99.97%) of copper strip and rolls provides the premium quality needed f or many projects and applications in a wide range of industries and uses.

Copper strip and rolls are in red and pink color and is known for its excellent malleability and ductility. Copper strip and rolls provide excellent strength, good corrosion resistance, superior electrical conductivity and non-sparking capabilities.

Our copper strip is available in thickness from 0.05mm to 3.0mm. The copper foil is in thickness from 0.05mm to 0.15mm, and copper strip or rolls is in thickness from 0.15mm to 3.0mm. The temper of copper strip and rolls is in 1/4 hard, 1/2 hard, 3/4 hard, hard and annealed. Our copper strip ad rolls are produced according to ASTM B152 standard.

Material

Copper strip and copper foil are made from material in compliance with:

C12200 (Cu-DHP) alloy, with copper content more than 99.90% and with phosphorous range of 0.015% to 0.040%

C11000 (Cu-ETP) alloy, with copper content more than 99.90%, with superior electrical conductivity more than 100% IACS

Key Feature

Excellent strength, good corrosion resistance

Superior electrical conductivity, more than 100% IACS

Strong sea-worthy wooden case for maximum protection

Thickness available from 0.05mm to 3.0mm

Full range of temper: 1/4 hard, 1/2 hard, 3/4 hard, hard and annealed

Standard: ASTM B152

Technical Properties

Copper Alloy | Chemical Composition | Temper | Mechanical Property | Electrical Conductivity IACS (%) | ||

Copper % | Phosphorus % | Tensile Strength MPa | Elongation % | |||

C12200 | ≥ 99.90 | 0.015-0.040 | 1/4 Hard | 235-295 | ≥ 25 | / |

C12200 | ≥ 99.90 | 0.015-0.040 | 1/2 Hard | 255-315 | ≥8 | / |

C12200 | ≥ 99.90 | 0.015-0.040 | 3/4 Hard | 285-345 | / | / |

C12200 | ≥ 99.90 | 0.015-0.040 | Hard | 295-360 | / | / |

C12200 | ≥ 99.90 | 0.015-0.040 | Annealed | 205-260 | ≥ 30 | / |

C11000 | ≥ 99.90 | / | 1/4 Hard | 235-295 | ≥ 25 | ≥ 97 |

C11000 | ≥ 99.90 | / | 1/2 Hard | 255-315 | ≥8 | ≥ 97 |

C11000 | ≥ 99.90 | / | 3/4 Hard | 285-345 | / | ≥ 97 |

C11000 | ≥ 99.90 | / | Hard | 295-360 | / | ≥ 97 |

C11000 | ≥ 99.90 | / | Annealed | 205-260 | ≥ 30 | ≥ 100 |

Specifications

Alloy | Form | Temper | Size (mm) | ||

Thickness | Width | Length | |||

C11000, C12200 | copper foil copper strip | Hard, 3/4 Hard, 1/2 Hard, 1/4 Hard, Annealed | 0.05-0.15 | ≤300 | Roll |

≥0.15-0.5 | ≤600 | Roll | |||

≥0.5-3.0 | ≤1000 | Roll | |||